Materials Test Lab Accuracy: Your Portal to Superior Quality Assurance

Wiki Article

Advanced Materials Testing Solutions for Reliable Results

In the realm of materials testing, accuracy and accuracy are of utmost value. With the ever-increasing intricacy of innovative products, it is essential to depend on robust and dependable screening remedies. This is where innovative products screening services enter into play. These remedies use sophisticated techniques and cutting edge analytical tools to ensure accurate and thorough outcomes.Non-destructive testing strategies permit extensive examination of materials without endangering their stability. Advanced logical instruments offer valuable understandings right into the homes and actions of products at a microscopic degree. High-temperature testing options enable the analysis of materials' performance under extreme problems.

Additionally, progressed mechanical testing techniques provide a much deeper understanding of the mechanical properties of materials. Personalized screening services deal with particular needs and difficulties of numerous industries.

By utilizing these advanced products evaluating services, markets can with confidence make informed decisions based upon trustworthy and reputable outcomes.

Non-Destructive Examining Strategies

Non-destructive testing methods play a critical duty in making certain the reliability of sophisticated products by permitting accurate evaluation without triggering damages. These strategies are essential in industries that rely upon the performance of products such as aerospace, auto, and building.Among one of the most usual non-destructive screening strategies is Aesthetic Inspection, which involves checking the surface area of a material for flaws, such as fractures, rust, or delamination. This strategy is cost-effective and basic, making it a prominent option in lots of markets.

Another widely utilized technique is Ultrasonic Screening (UT), which uses high-frequency sound waves to spot interior defects or inconsistencies in materials. By evaluating the reflection of audio waves, UT can supply important info about the density, honesty, and thickness of a material. This strategy is especially efficient for spotting surprise splits or spaces in steels, compounds, and other products.

Magnetic Fragment Checking (MT) is an additional non-destructive strategy that is typically used to identify surface and near-surface flaws in ferromagnetic materials. By applying magnetic areas and magnetic bits to the material, MT can determine splits, seams, and other blemishes that could jeopardize its architectural integrity.

Advanced Analytical Instruments

Utilizing sophisticated technology, advanced analytical instruments offer specific analysis of materials for reliable results. These instruments play an essential function in products screening, allowing researchers and engineers to gain a deeper understanding of the make-up, structure, and properties of different products.

An additional crucial tool is the X-ray diffractometer (XRD) XRD enables researchers to evaluate the crystal framework of materials by gauging the diffraction pattern of X-rays that connect with the example. This technique supplies info concerning the setup of atoms within the product, aiding to determine phases, crystallographic issues, and grain alignments.

In addition, progressed logical tools likewise consist of Fourier-transform infrared spectroscopy (FTIR), which examines the communication between infrared radiation and a product to determine its chemical composition and useful teams. Furthermore, techniques such as atomic pressure microscopy (AFM) and energy-dispersive X-ray spectroscopy (EDS) are utilized to examine surface topography and important structure, respectively.

High-Temperature Screening Solutions

To address the challenges of products evaluating at heats, specialized remedies have been created to make certain accurate and reliable outcomes. High-temperature testing is crucial in numerous industries, such as aerospace, vehicle, and energy, where products should stand up to extreme problems. These options include the usage of innovative devices and strategies that can deal with and simulate extreme temperatures.

Another essential aspect of high-temperature testing solutions is the development of advanced measurement and analysis techniques. These strategies allow researchers to properly track the actions and check of products under severe temperature levels. Non-contact dimension methods, such as thermal imaging and spectroscopy, are frequently made use of to examine thermal conductivity, development, and other crucial material residential properties.

Furthermore, high-temperature testing remedies usually involve using sophisticated materials, such as refractory steels and ceramics, that can hold up against severe heat without jeopardizing their structural honesty. These products are utilized in the construction of components, sensing units, and other components needed for precise testing.

Advanced Mechanical Checking Methods

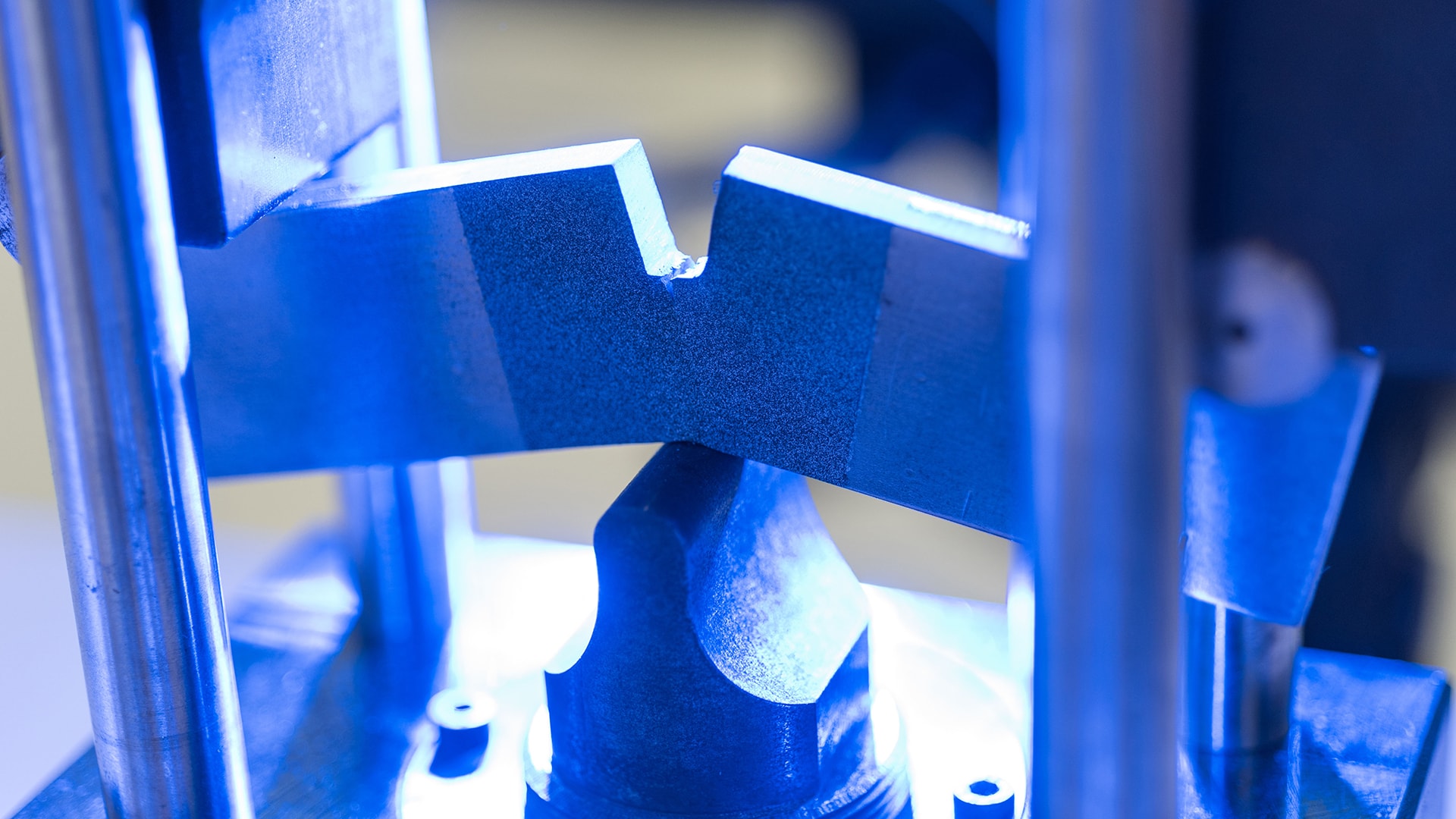

One commonly made use of mechanical testing technique is tensile screening, which applies a regulated pressure to a product example to determine its capacity to stand up to stress. This test assists establish crucial mechanical properties such as ductility, stamina, and use this link flexibility.

One more sophisticated mechanical screening method is firmness testing, which gauges a product's resistance to impression or penetration. This test is critical for assessing a product's capability to hold up against wear, deformation, and crack.

Furthermore, fatigue screening is used to evaluate a product's resistance to repeated loading, imitating real-life problems where components experience cyclic anxieties. This test is especially crucial for industries such as aerospace and automobile, where the discover here dependability and longevity of materials are vital.

In enhancement to these techniques, advanced mechanical testing includes effect screening, creep screening, and crack sturdiness screening, to name a few. These techniques offer useful insights right into a product's actions under different mechanical problems and assist make sure the dependability and security of various applications.

Custom-made Examining Solutions

Personalized screening remedies are tailored to satisfy certain requirements and provide trusted and accurate outcomes in materials screening. When it involves testing products, there is no one-size-fits-all technique. Each material has one-of-a-kind residential or commercial properties and characteristics that call for specialized testing approaches. Custom-made testing remedies make sure that these certain requirements are satisfied, allowing for exact and reputable outcomes.One of the primary benefits of customized testing options is their versatility. They can be made to suit a wide variety of materials, including metals, compounds, polymers, and ceramics. By understanding the distinct residential or commercial properties of each product, screening specifications can be maximized to make certain exact and reliable results.

One more benefit of customized testing solutions is their ability to resolve details screening demands. Whether it is examining the mechanical residential or commercial properties, fatigue behavior, or thermal security of a material, a customized approach can be created to satisfy these requirements. This makes sure that the screening procedure is effective and reliable, conserving time and sources.

Customized screening remedies additionally supply the benefit of flexibility. As brand-new products and screening needs emerge, these solutions can be modified and upgraded to fit the modifications. This makes sure that the testing procedure remains relevant and updated in an ever-evolving industry.

Conclusion

Finally, advanced products examining services supply dependable outcomes through non-destructive testing methods, progressed analytical tools, high-temperature screening services, progressed mechanical testing techniques, and personalized screening solutions. These tools and techniques play a crucial role in making sure the quality and performance of materials in different sectors. Using these advanced testing techniques can improve the understanding, characterization, and optimization of products, leading to improved product advancement and general effectiveness.my site With the ever-increasing intricacy of innovative products, it is essential to depend on durable and reliable screening remedies (materials test lab). High-temperature screening remedies enable the analysis of materials' efficiency under extreme conditions

Personalized testing solutions are tailored to meet details needs and give dependable and precise results in materials testing.An additional advantage of personalized screening solutions is their ability to resolve details screening requirements.In verdict, progressed products examining remedies supply trusted outcomes with non-destructive testing methods, advanced logical tools, high-temperature screening solutions, progressed mechanical screening approaches, and personalized screening options.

Report this wiki page